3S-Smart Software Solutions has since pretty long had a Raspberry Pi (RPI) target image available for their CODESYS runtime. The intention was to create something that you could buy very cheap, primarily for students and such to learn how to program 61131-3.

As I’m primarily working with TwinCAT 3, which is based on CODESYS, I’ve been thinking about building a really cheap 61131-3 compatible PLC based on the RPI and the CODESYS target. I didn’t just want it to be one board laying around in my home, but I also wanted it to have the “industrial” feeling, and luckily I found a perfect development board + case for me to initialize the project. Now that it’s finished, I have a PLC running an EtherCAT master in the CODESYS runtime for almost no money at all.

The raspberry PI (RPI) is really awesome in that it gives the possibility to build really small embedded systems with a very small investment. Now it’s also possible to run a fully 61131-3 compatible programmable logic controller (PLC) as CODESYS have a RPI target runtime. This is also supplied with loads of extras, with built-in support for EtherCAT, Modbus RTU/TCP, Profinet and much more. Your program code can run for 120 minutes before they stop, and for a mere 35€ you can buy a license which allow you to run your programs in their runtime indefinitely in once instance of the RPI.

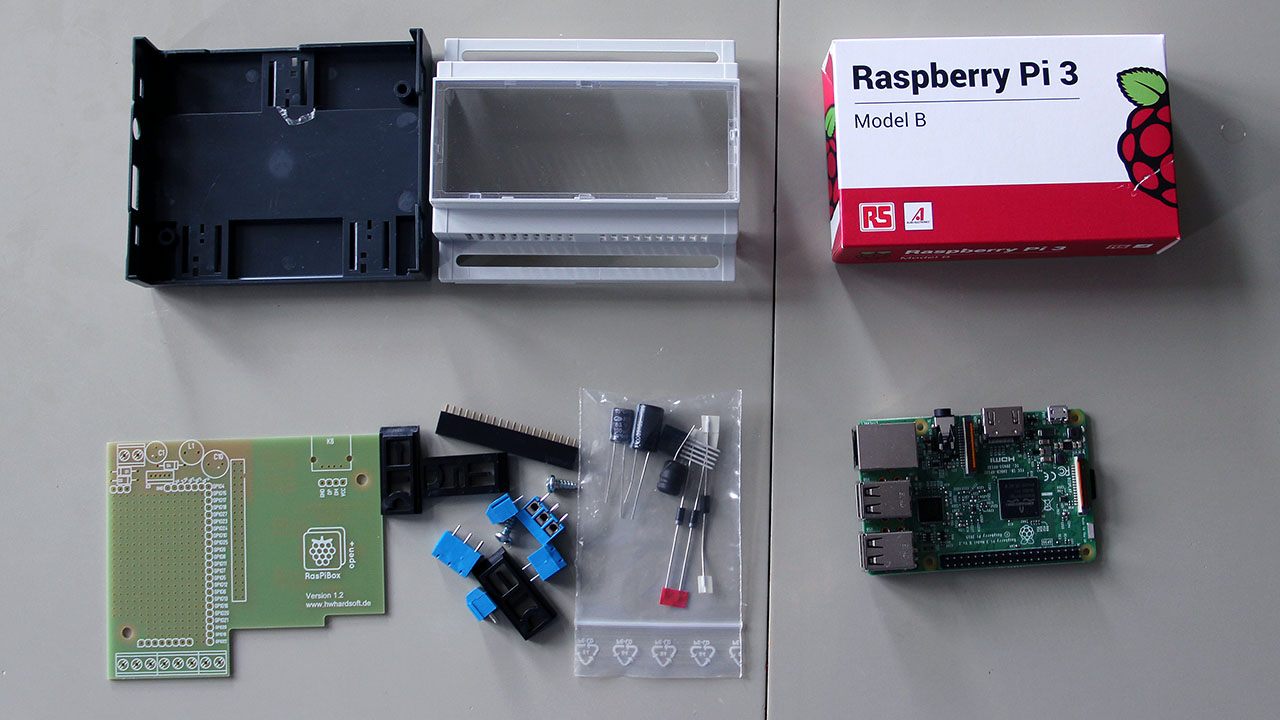

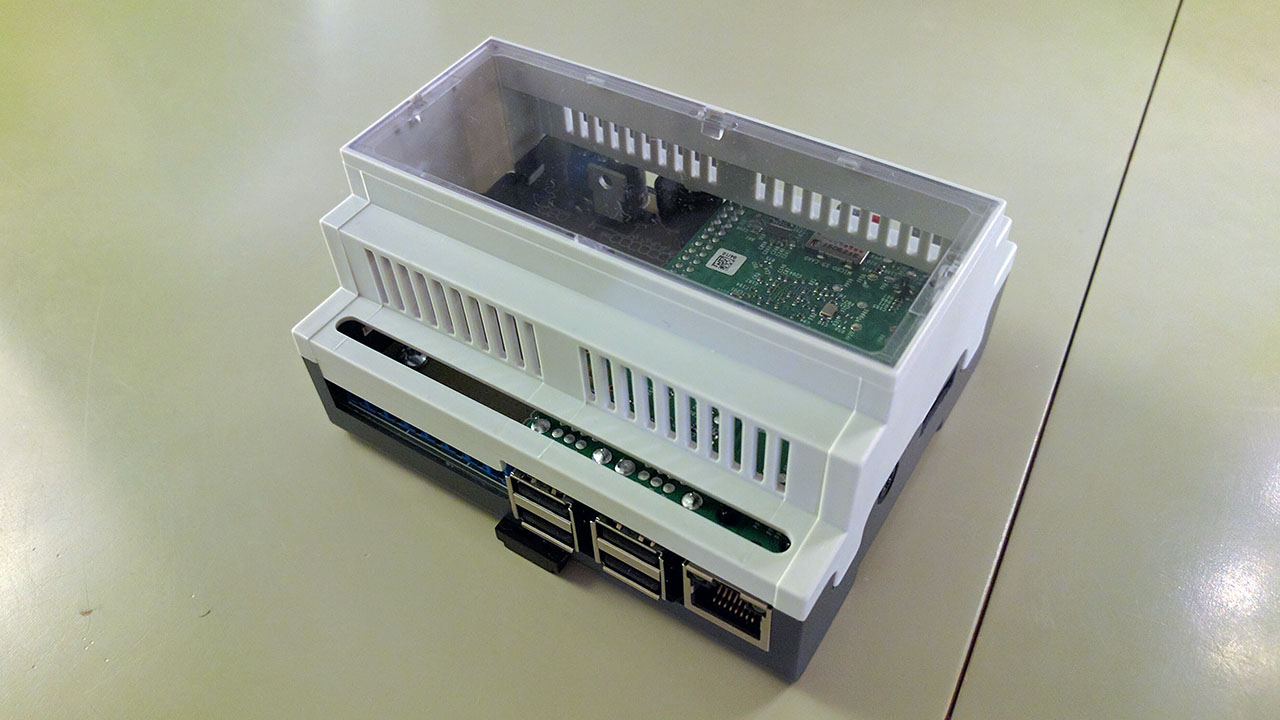

I decided to built a PLC with the RPI, but in a slightly more industrial DIN-mountable casing. I found the RasPiBox open solution which was perfect. It includes not just the enclosure, but also a prototyping board, terminal blocks and a voltage regulator (9-35V DC) which makes the RPI-solution feel even more like a real PLC.

Hardware & Software Link to heading

The hardware used to build this:

- A raspberry PI 3B

- The RasPiBox standard

- A soldering iron and some solder

- A microSD card

And software used:

- Raspbian Jessie lite – built 2016-09-23, kernel 4.4

- CODESYS V3.5 SP9 Patch 3+

- CODESYS control for raspberry PI – version 3.5.9.20

Built instructions Link to heading

First I installed Raspbian on the SD-card using the instructions provided by the raspberry pi webpage. The next step was to download and install the CODSYS control for Raspberry PI package after the official instructions. Even though the package is free to try for evaluation (again, 120min limit) you need to register to download it.

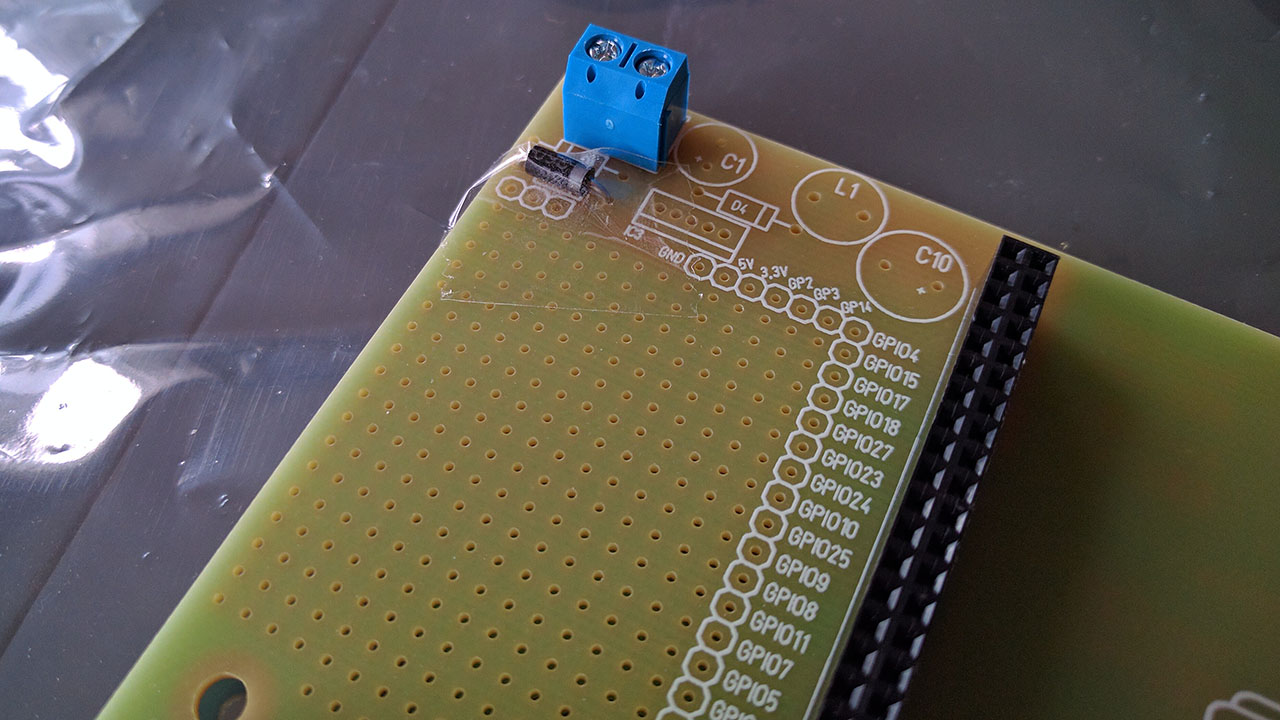

Start by soldering all the parts into place according to the instructions provided with RasPiBox. I usually temporarily add some tape for the parts so they stick firmly at their location before applying the solder. Might not be so beautiful, but it’s temporary and if it works it ain’t stupid…

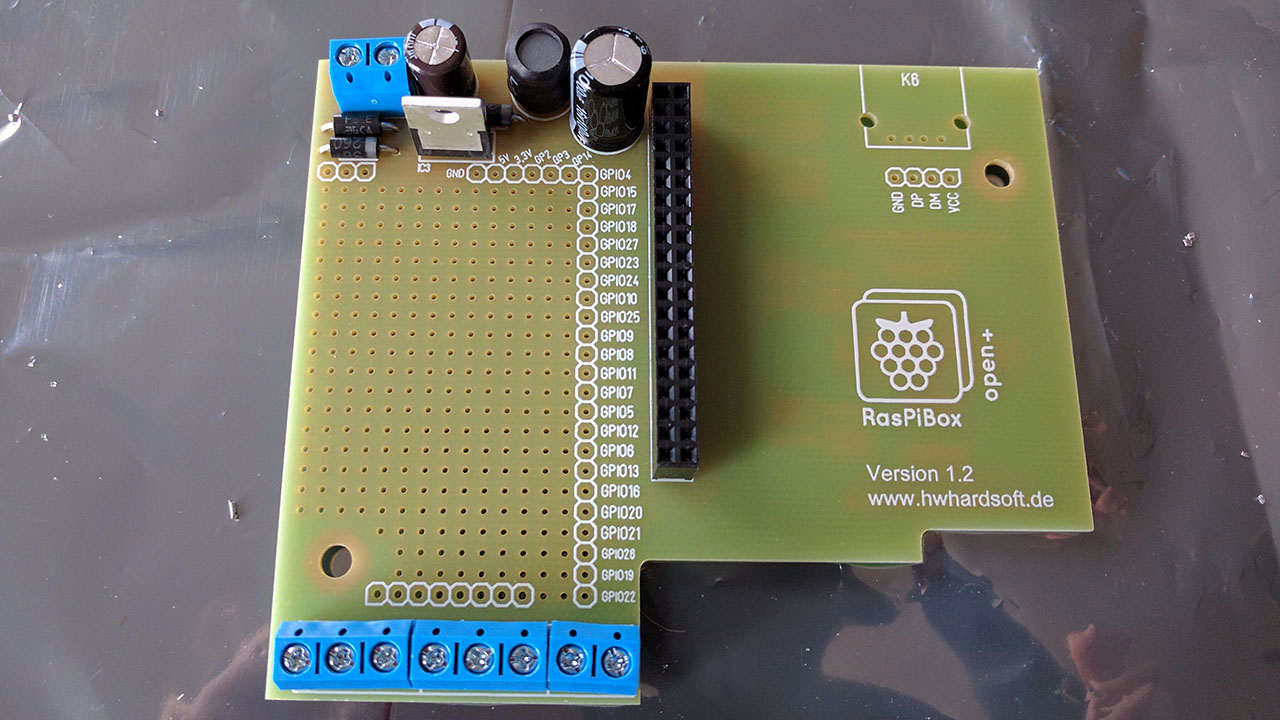

And this is how it looks once everything is soldered into place.

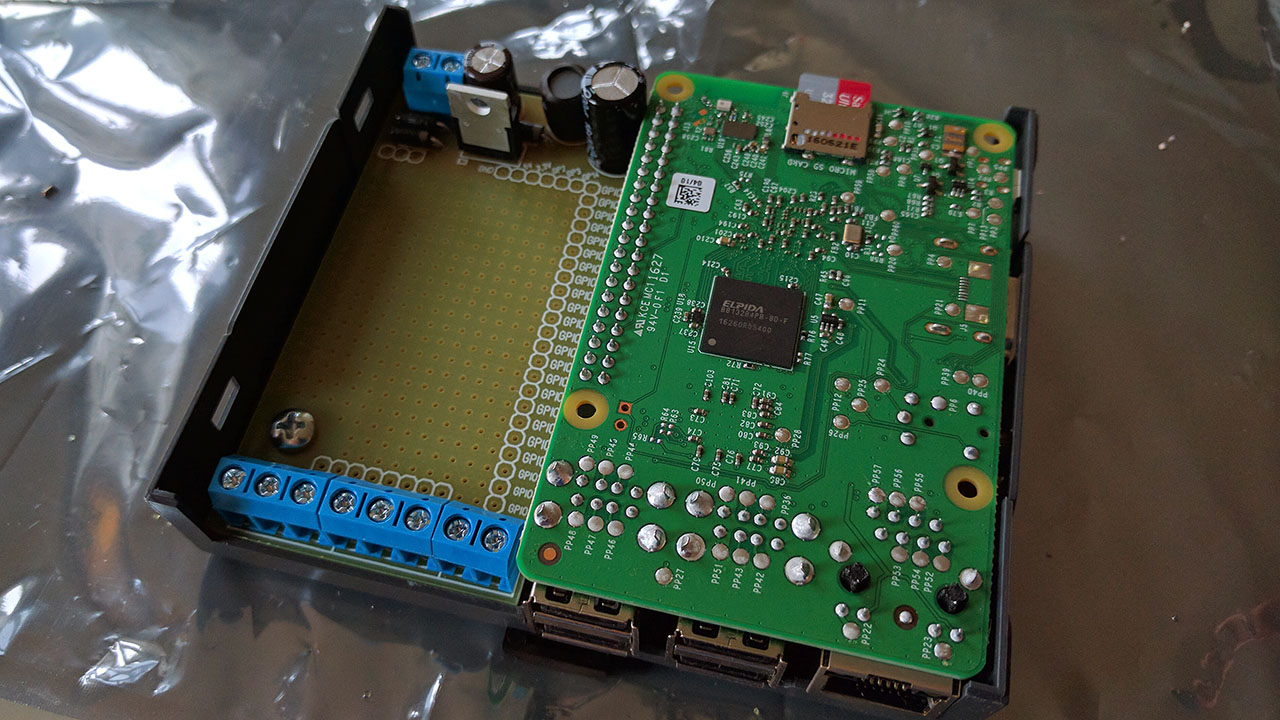

And then just mount the board into the box and attach the Raspberry PI.

The front face attached to the rest of the body, and voila! It actually looks like an industrial PLC now.

Now it was time to test it. As the voltage regulator allows me to connect a power supply between 9-35V DC, a standard UPS of 24V works just fine.

I will try this running as an EtherCAT master and also do some Modbus TCP/RTU communications. The complete cost of this project was:

- Raspberry PI 3 – 38€

- 32gb microSD – 11€

- RasPiBox – 37€

totaling 86€. Top that with a license for CODESYS (35€) and you’ve got a full 61131-3 compatible PLC controller supporting various fieldbuses, I doubt you can get away any cheaper than that!